RHR Performance, a company that never misses a chance to weigh something, we have an update to our "Not All Composite Parts Are Created Equal" series. You can read part 1 here and part 2 here (INSERT NEW LINKS). It may be beneficial to read them as a primer to this. In this installment we will measure a competitors' E46 BMW hood. We won't name this particular company, but I am dumbfounded after weighing this part. Keep in mind that an aluminum M3 hood is just about 24lbs. I hung this hood from the scale and watched it climb past an OEM hood up to just over 26lbs! You have to almost try to make a composite hood HEAVIER then an OEM hood.

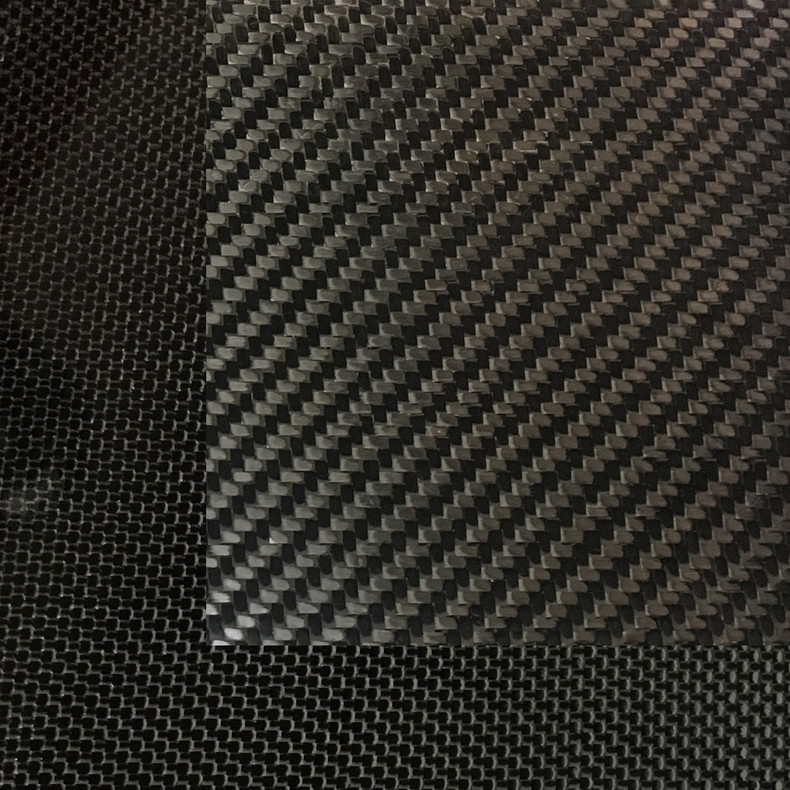

If you read part 1 and 2, you will be aware of the advantages of proper layups coupled with proper materials and processes to yield a part that is much stronger and lighter. This is why we make our parts with 100% carbon fiber with a resin infusion process and are able to offer our E46 Carbon Fiber hoods at just 9.7lbs. With our new in mold clear options that will bump up to just over 10lbs. Still a substantial weight savings over even an aluminum hood. So if you are buying a hood just for the carbon look, then I get it. But if you are buying a hood for a performance advantage, be sure to know what you are buying. If the company doesn't post a parts' weight, or disclose that their "carbon fiber" part is either carbon every layer, or backed with fiberglass, then evaluate your options and proceed from there.