In this installment of Project Crusher, we are happy to report the design & CFD are complete and we are now working on manufacturing the molds. Some of the parts are complex and to keep mold production costs down, we are working with a combination of 3D printing, CNC cut foam, and machined metal.

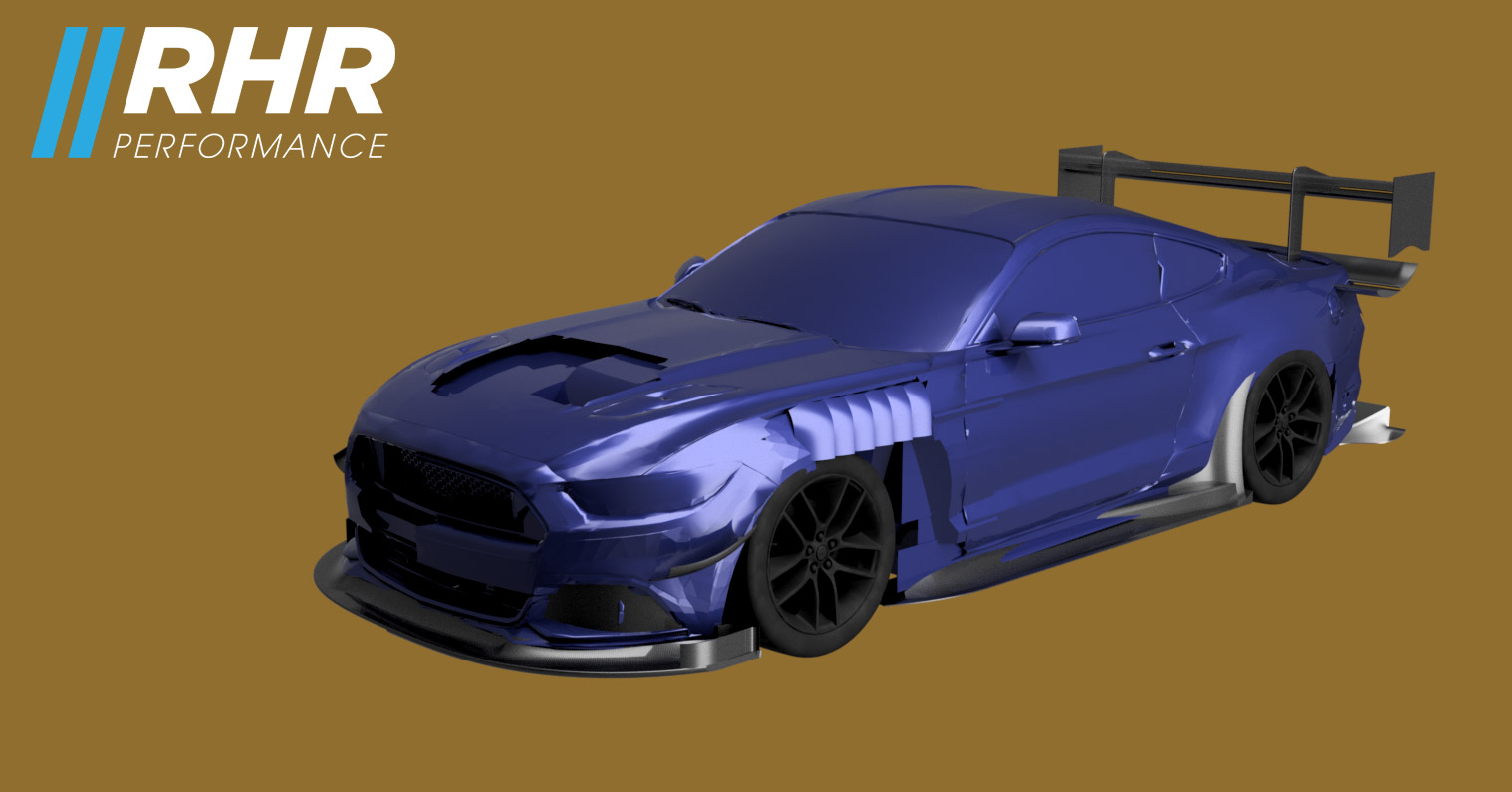

Fig- AI Spec w/ Rear Canards

In all, Project Crusher has 7 aerodynamic devices (some of these have subsystems that we’ll get into detail when we cover that part). The list is:

- Wing (Nike 12 for AI, Nike 17 for ST)

- Rear Diffusor (Dirty Floor version for AI, Flat Floor version for ST)

- Front Canards (1 pair for AI, 2 pair of 3D airfoils for ST)

- Front Splitter/Diffusor (Tunneled and 3D splitter for AI, Tunneled and 3D Infinity Splitter for ST)

- Rear Canards (AI Only- Nike 17 profiles, only needed when an extreme amount of rear downforce is required)

- Side Skirts (common to both AI and ST)

- Flat Floor (ST only)

- Hood Vent (Common to both AI and ST)

- Fender Vent (Common to both AI and ST)

- Foglight block off (Common to both AI and ST)

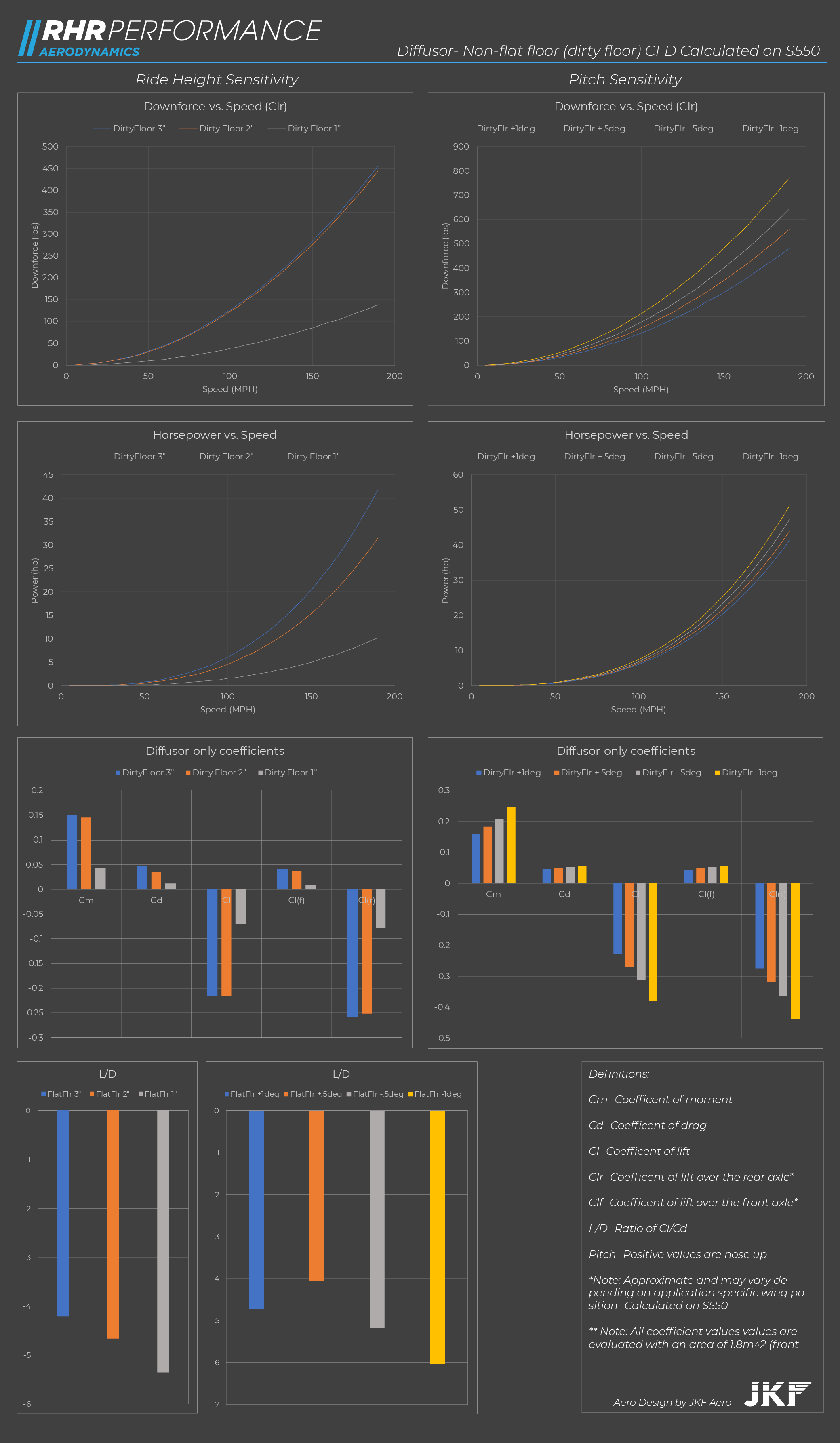

In addition, there is a now full aero map of the car with ride height and pitch sensitivity sweeps, center of pressure balance, and coefficients for every part. It’s many, many sheets of excel data, so it will take some time to publish. Our objective is make these aero parts available to all along with the aero maps.

To give a sense of the downforce we are talking about, the ST version makes about 2.2 to 2.6 Cl, which is near F1 territory of 3.0 (and we base our coefficients on a frontal area of 1.8m^2, so we aren’t “cheating” like some do by only evaluating the coefficient on the wing or part area). The AI Spec DF coefficient is around 1.6

Today we are concentrating on the diffusor for the AI spec iteration which doesn’t allow for a flat floor.

Since the 3D models we purchase are highly detailed on the exterior and interior, but have a very simplistic underbody model, we had to take measurements and draft our own underbody- frame rails, exhaust, driveshaft, differential, and fuel tanks to accurately model the under body aero. This allows us to get a more accurate representation of real world numbers.

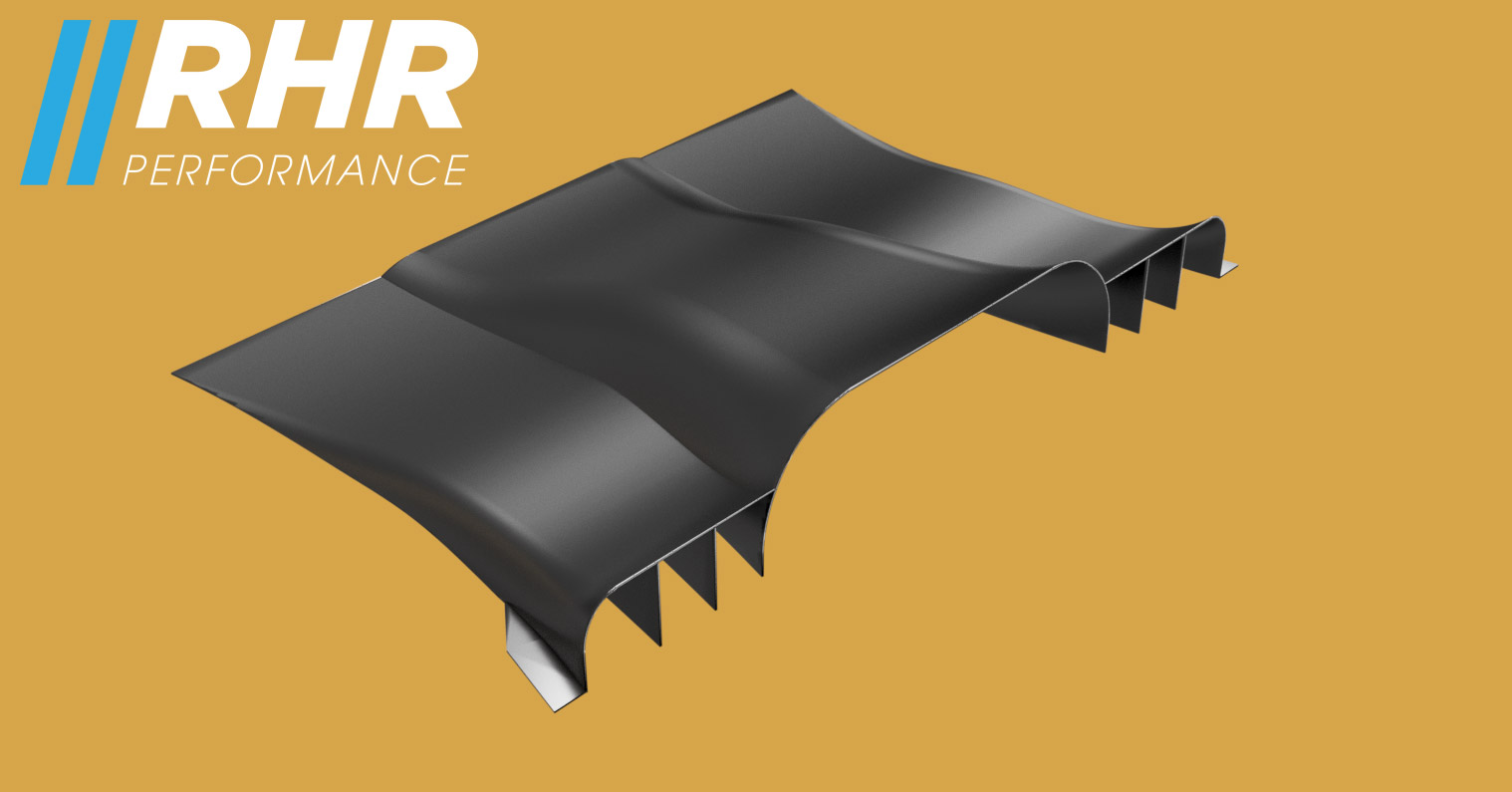

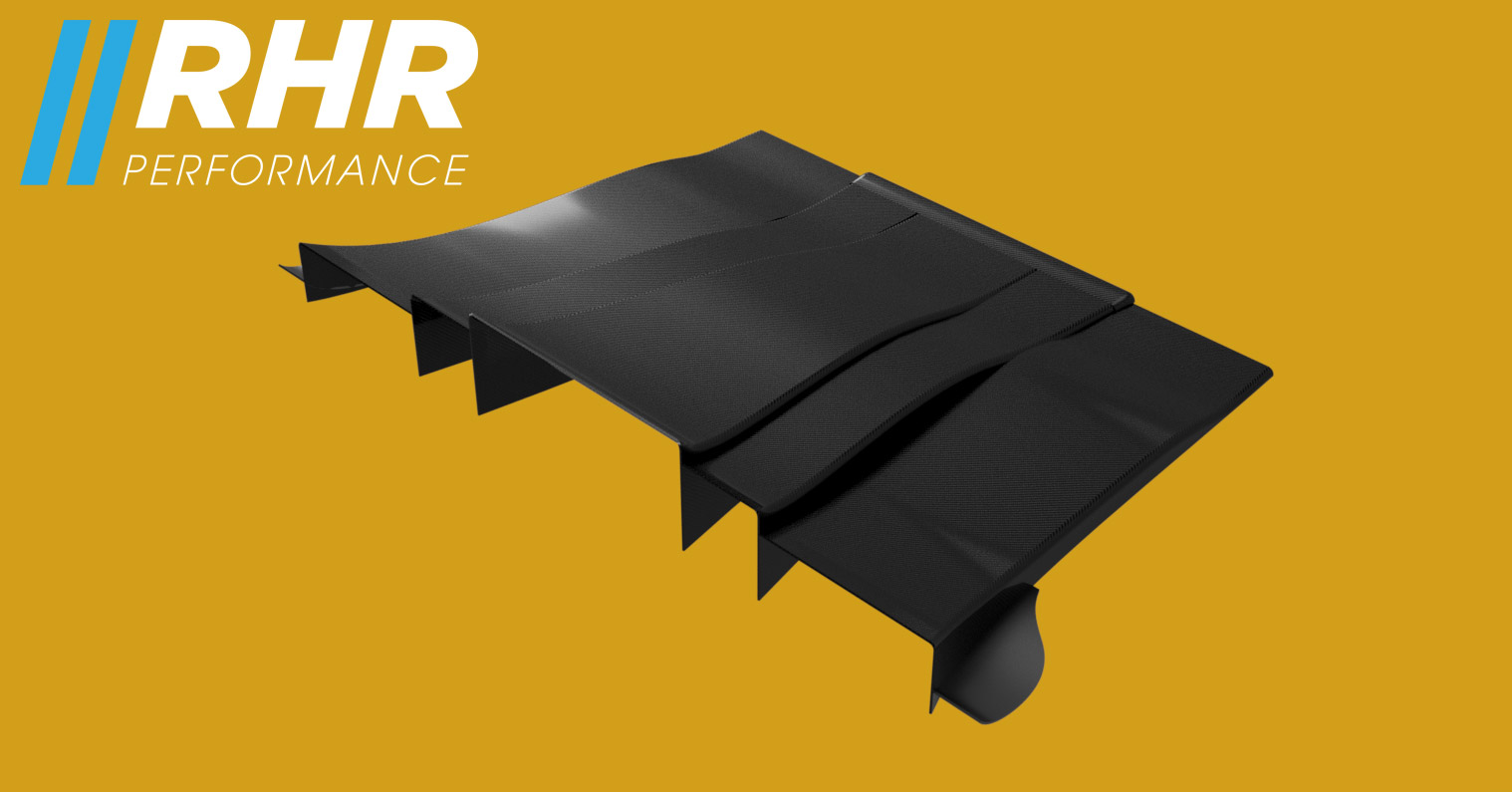

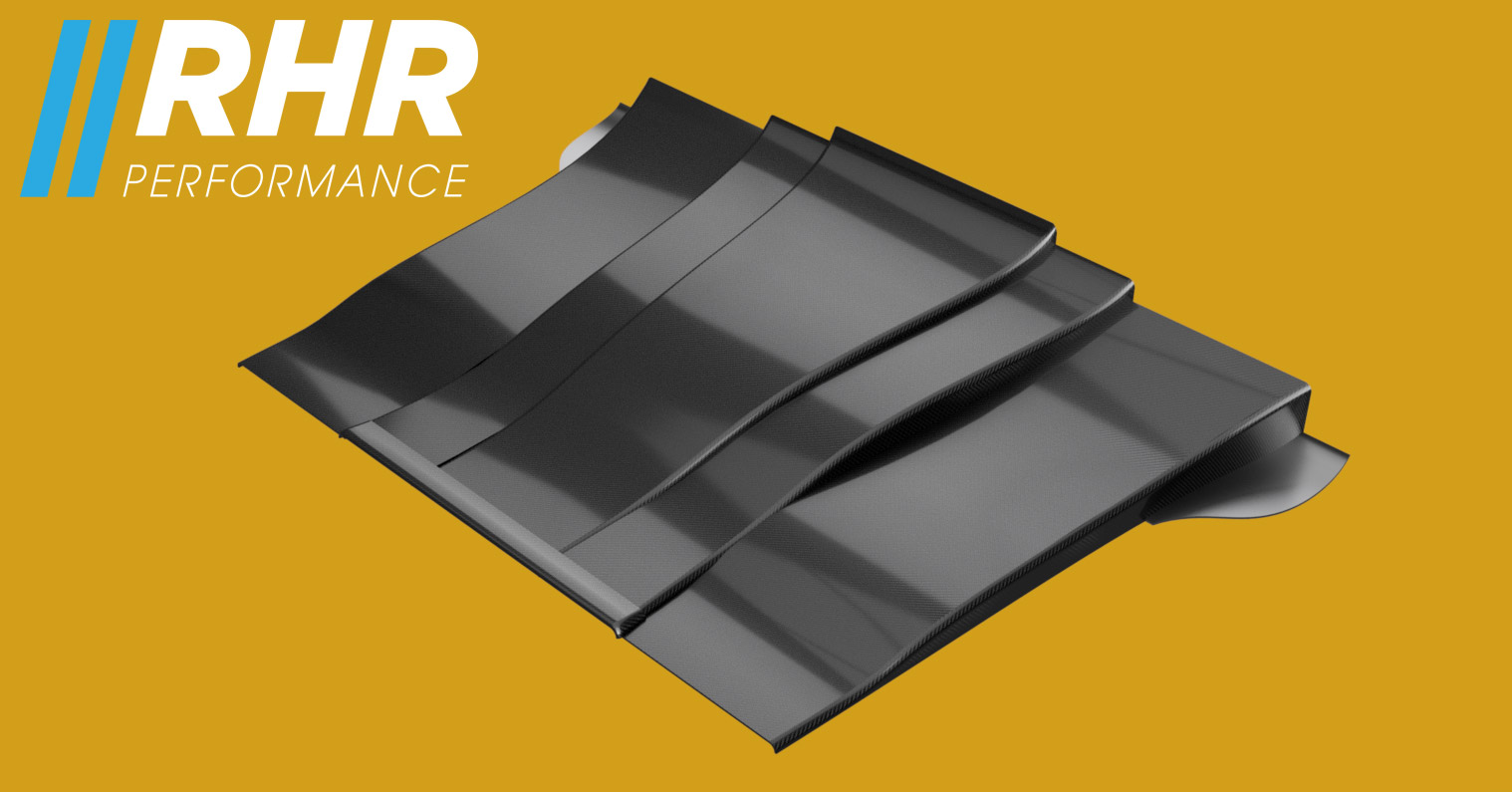

Our Aero consultant, Kyle, as usual, started with what would work the best- a highly curved diffusor that would be difficult to manufacture without a large 5 axis CNC. We talked this process through and arrived at a compromised design of tunnel blocks capable of multiple 2D CNC hot wire foam cuts. Kyle being really good at what he does was able to get the performance of the simpler diffusor where he wanted it by iterating and re-iterating the design until it just about matched the performance of his initial approach.

Fig- Unmanfacturable diffusor

Fig- Workable & modular diffusor

Kyle then designed two iterations of the diffusor, although the only difference is that the non-flat floor version has a radiused profile on the leading edge of the diffusor. It certainly looks strange because it does produce localized lift, but since air is flowing above and below the diffusor, the marginal lifting effect is ameliorated by ensuring the airflow stays attached to the upper surface of the diffusor

Fig- Wing profile on leading edge

The construction of the splitter will be modular- each tunnel will be molded individually, and then either bonded or attached with mechanical fasteners. We are still debating the merits of both approaches- using mechanical fasteners means that it’s possible to damage a tunnel or two, yet not destroy the entire part, meaning repair costs will be less, and also packaging as individual tunnels means it may ship in a smaller box for reduced shipping costs.

Fig- Workable & modular diffusor

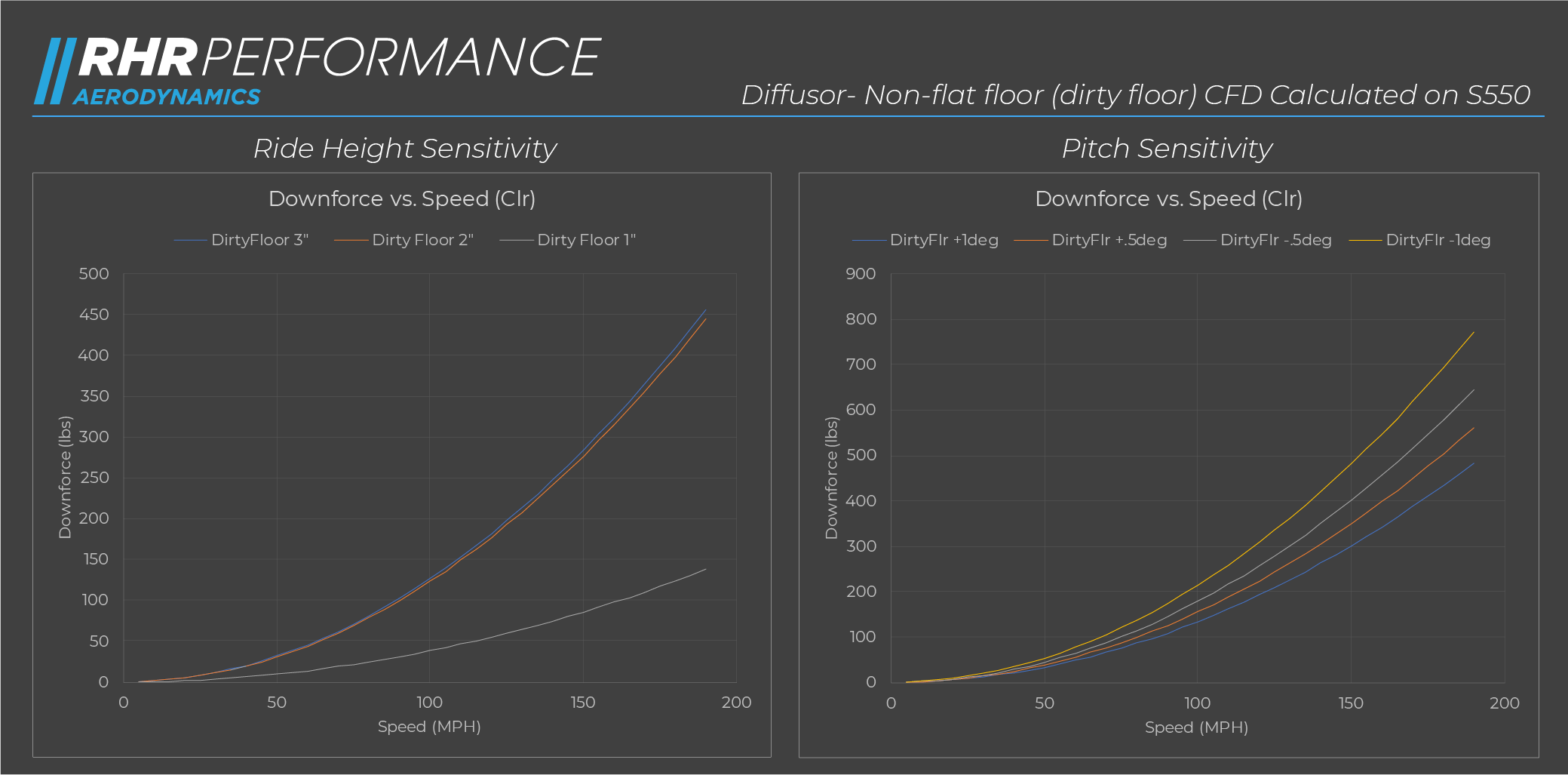

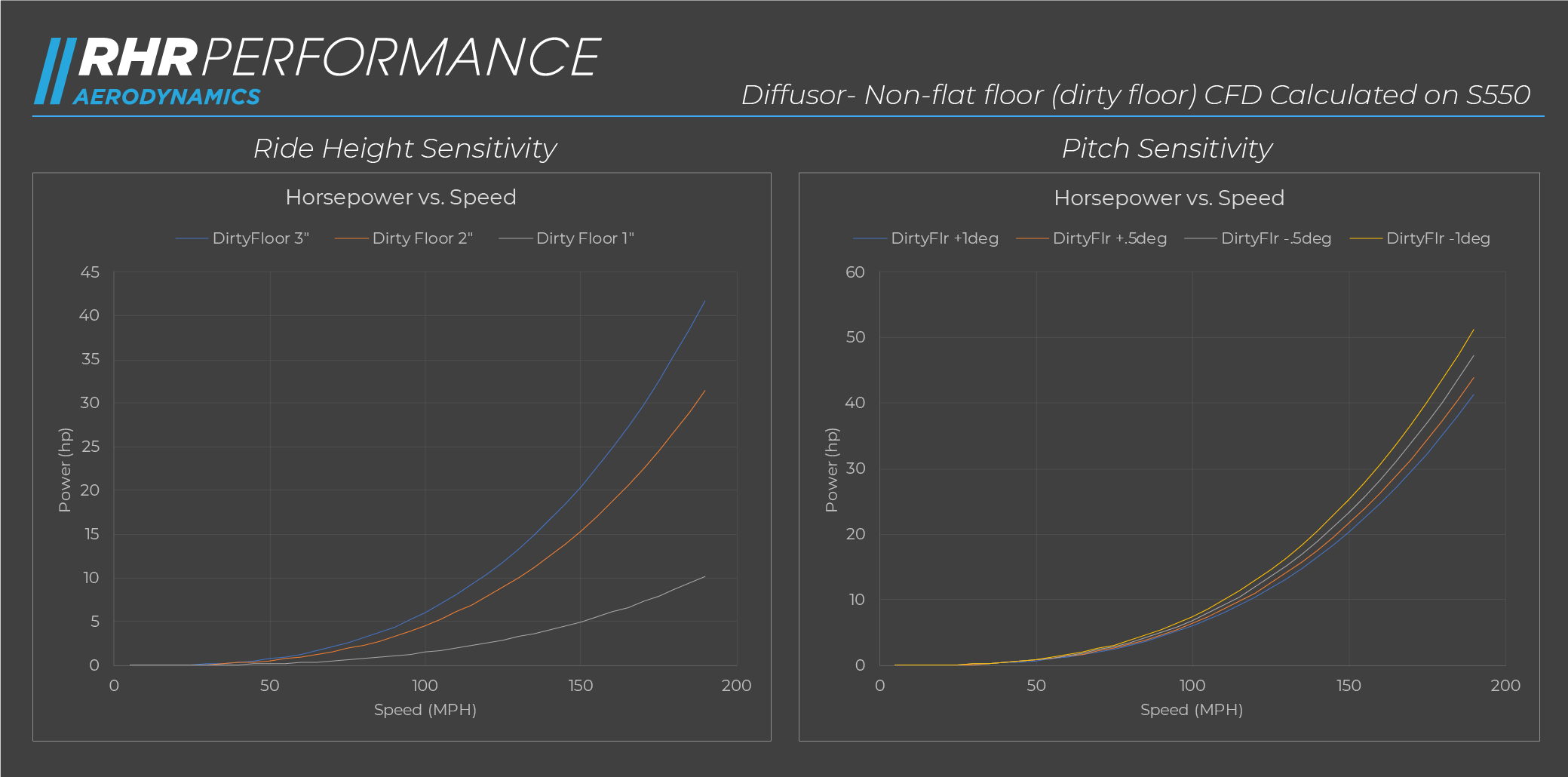

Here are some DF numbers, note especially that when the suspension is compressed, the airflow to the diffusor is choked off and it loses effectiveness- when we present the flat floor diffusor, you’ll see a different story. All in all, this is a pretty amazing diffusor for DF to horsepower required. We think it’s going to be dynamite.

Downforce Sweeps w/ Ride Height and Pitch

Horsepower Sweeps w/ Ride Height and Pitch

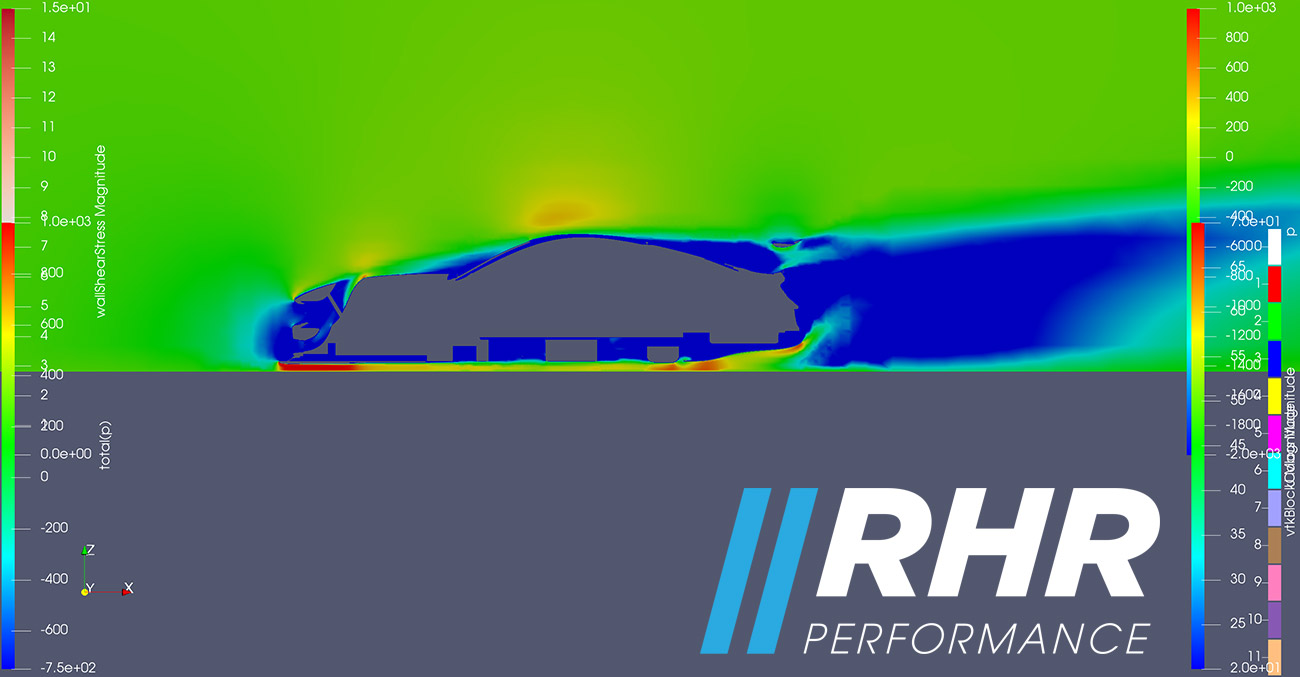

Velocity Slice @ 3" Ride

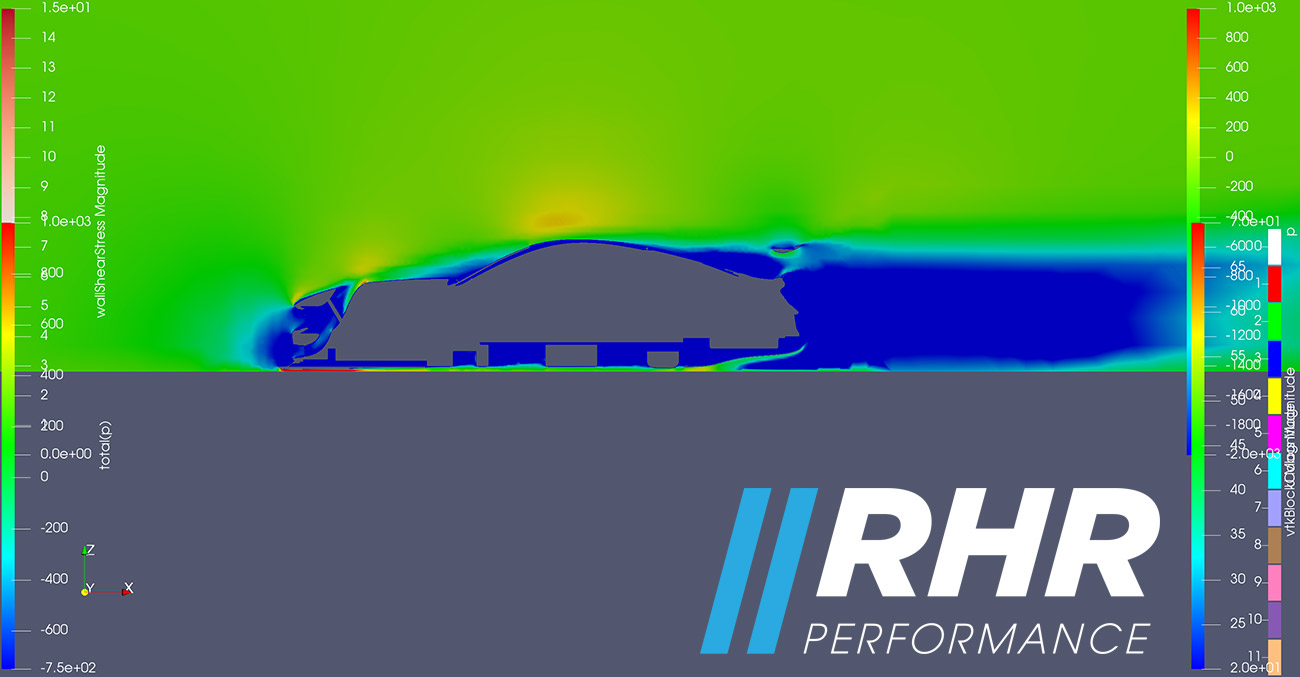

Velocity Slice @ 1" Ride

Full Data Plots